The Art of Aluminum Part Manufacturing

When it comes to precision engineering in the Home & Garden and Appliances industry, the role of aluminum part manufacturers cannot be overlooked. Wetron Industrial stands out as a leading provider in this sector, known for its commitment to quality, craftsmanship, and innovation. Let's delve into the world of aluminum part manufacturing and discover why choosing a reliable manufacturer like Wetron Industrial can elevate your business to new heights.

Benefits of Aluminum Parts in Home & Garden, Appliances

Aluminum is a versatile metal that offers a range of benefits when used in the manufacturing of parts for the Home & Garden and Appliances sector. Its lightweight nature, corrosion resistance, and durability make it an ideal choice for various applications. From structural components to decorative elements, aluminum parts play a vital role in enhancing the performance and aesthetics of products.

Why Choose Wetron Industrial?

With a proven track record of delivering top-notch aluminum parts to clients in the Home & Garden and Appliances industry, Wetron Industrial has earned a reputation for excellence. Here are some compelling reasons to partner with Wetron Industrial:

- Quality Assurance: Each aluminum part manufactured by Wetron Industrial undergoes rigorous quality control measures to ensure precision and consistency.

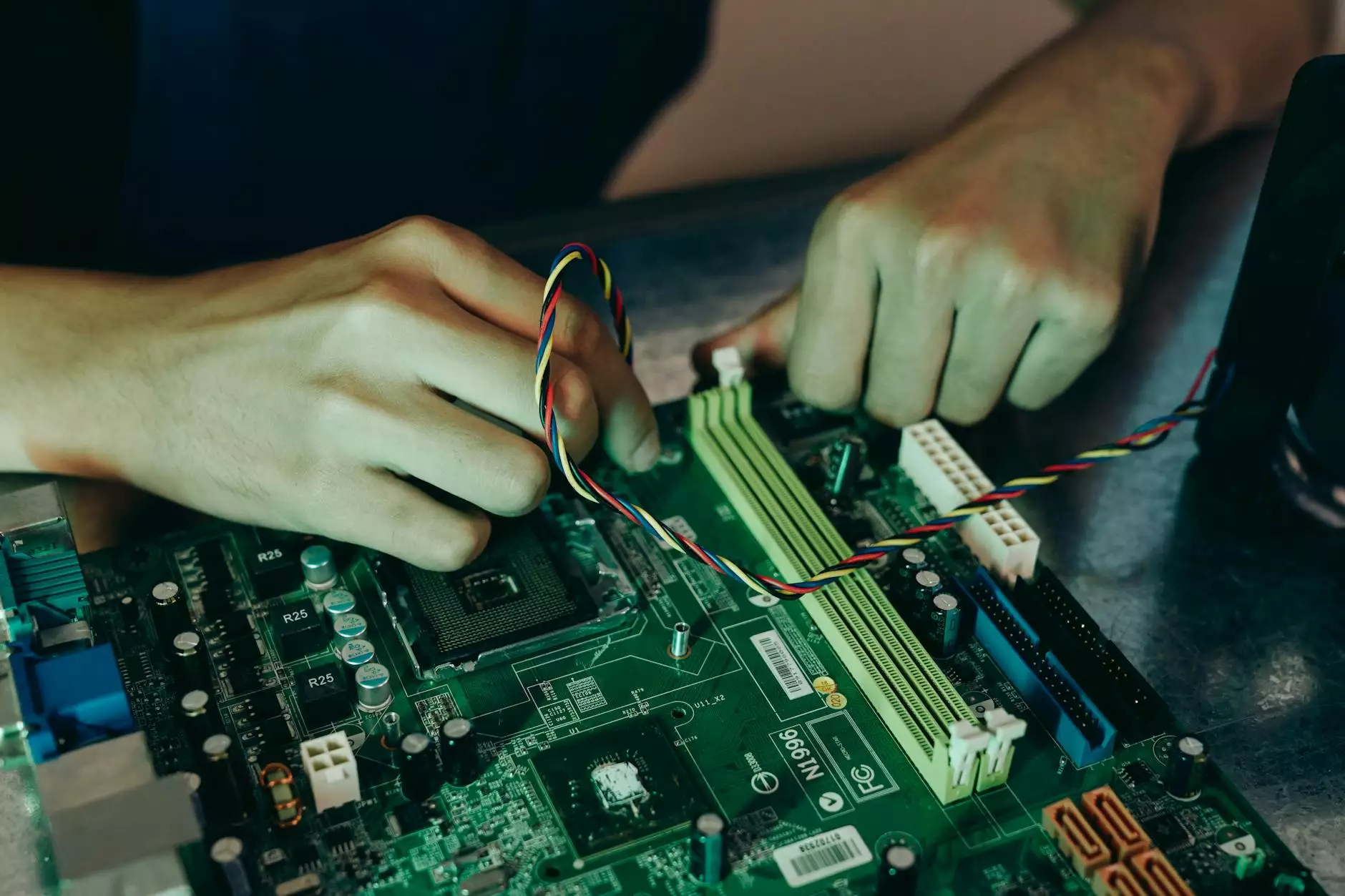

- Advanced Technology: Wetron Industrial utilizes state-of-the-art machinery and techniques to meet the diverse needs of clients across different sectors.

- Custom Solutions: From concept to production, Wetron Industrial offers tailor-made solutions to meet the specific requirements of each project.

- Timely Delivery: Meeting deadlines is crucial in the fast-paced Home & Garden, Appliances industry, and Wetron Industrial prides itself on its punctuality.

Aluminum Part Manufacturing Process

At Wetron Industrial, the manufacturing process of aluminum parts is a blend of art and science. From initial design concepts to the final product, every stage is meticulously planned and executed to perfection. Here's an overview of the typical manufacturing process:

- Design Phase: Collaborating with clients to understand their requirements and creating detailed blueprints for the aluminum parts.

- Material Selection: Choosing the right grade of aluminum based on the intended use and performance specifications.

- Machining: Using CNC machining and other precision tools to shape the aluminum into the desired form.

- Finishing Touches: Applying protective coatings, finishes, or treatments to enhance the appearance and durability of the parts.

- Quality Checks: Conducting thorough inspections to ensure that each aluminum part meets the highest standards of quality and accuracy.

Applications of Aluminum Parts

Aluminum parts manufactured by Wetron Industrial find diverse applications in the Home & Garden and Appliances sector. Some common uses include:

- Aluminum handles for kitchen appliances

- Aluminum frames for garden furniture

- Aluminum brackets for shelving systems

- Aluminum enclosures for electronic devices

Innovation in Aluminum Part Manufacturing

The field of aluminum part manufacturing is constantly evolving, driven by technological advancements and changing customer demands. Wetron Industrial stays at the forefront of innovation by investing in research and development to bring cutting-edge solutions to its clients. With a focus on sustainability, efficiency, and performance, Wetron Industrial is shaping the future of aluminum part manufacturing in the Home & Garden and Appliances industry.

Conclusion

Choosing the right aluminum part manufacturer is crucial for the success of your business in the Home & Garden and Appliances sector. With its unwavering commitment to quality, innovation, and customer satisfaction, Wetron Industrial emerges as a trusted partner for all your aluminum part manufacturing needs. Experience the difference that precision engineering can make in enhancing the value and performance of your products.