Unlocking the Importance of Instrument Sterilization Solutions

In the realm of healthcare, the safety of patients is paramount. One of the critical factors contributing to patient safety is the effective instrument sterilization solution implemented in medical facilities. The process of sterilizing instruments is a necessary practice to prevent infection and ensure that healthcare providers can offer the highest standard of care.

Understanding Instrument Sterilization

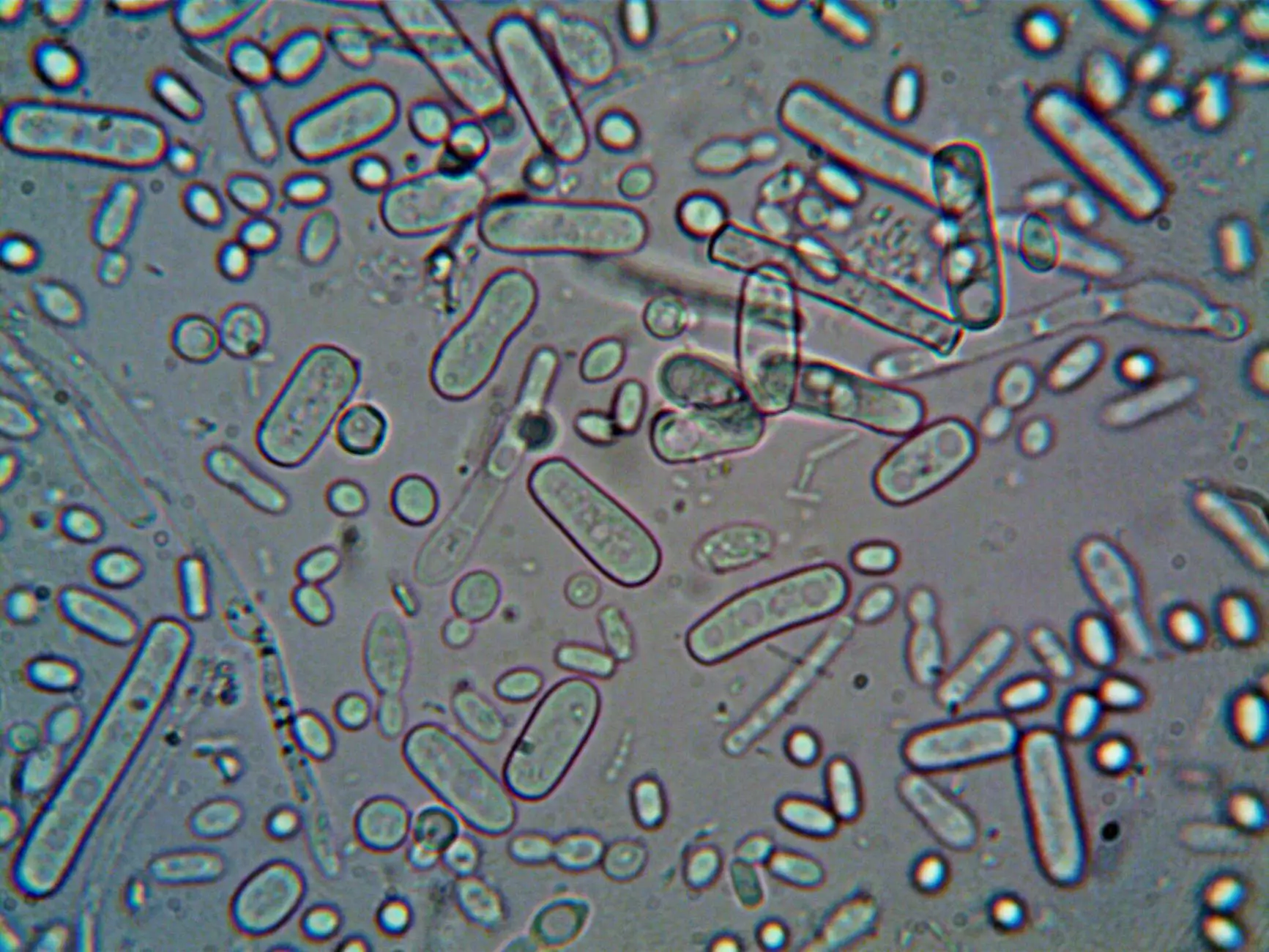

Instrument sterilization refers to the process of eliminating all forms of microbial life, including bacterial spores, from medical instruments and tools. Achieving this sterility is crucial in preventing healthcare-associated infections (HAIs) that can have severe consequences for patients.

The Need for Effective Sterilization

With an increasing number of medical procedures, the need for proper sterilization has become more evident. The following points highlight the necessity of robust sterilization practices:

- Prevention of Infections: Sterilization is essential to eliminate pathogens that could lead to infections.

- Compliance with Regulations: Healthcare facilities must adhere to strict regulations regarding instrument cleanliness and safety.

- Enhancing Patient Safety: Sterilized tools ensure that patients receive care without the risk of infection.

Types of Instrument Sterilization Solutions

There are several methods for instrument sterilization, each with its advantages and appropriate applications. Understanding these methods will help healthcare facilities choose the best solution for their needs.

1. Steam Sterilization (Autoclaving)

Steam sterilization, commonly known as autoclaving, is one of the most widely used methods for sterilizing medical instruments. This process involves exposing instruments to high-pressure steam at temperatures of at least 121°C (250°F) for a specified duration. The key benefits include:

- Cost-Effective: Autoclaves are relatively inexpensive to operate.

- Fast Processing Times: The process can be completed in as little as 15-30 minutes.

- Proven Efficacy: Steam sterilization is highly effective against a wide range of pathogens.

2. Chemical Sterilization

Chemical sterilization utilizes chemical agents like ethylene oxide (EtO) or hydrogen peroxide gas to achieve sterilization. This method is particularly useful for heat-sensitive instruments that cannot withstand high temperatures. Advantages include:

- Effective for Delicate Instruments: Allows for sterilization of items that cannot be autoclaved.

- Longer Shelf Life: Instruments can remain sterile for extended periods if properly stored.

3. Dry Heat Sterilization

Dry heat sterilization involves placing instruments in an oven that circulates hot air at temperatures of 160°C (320°F) for an extended period, typically 1-2 hours. This method is useful for items that might be affected by moisture, such as powders or oils. Benefits include:

- Suitable for Heat-Stable Materials: Ideal for glassware and metal instruments.

- No Corrosive Effects: Unlike steam, it does not cause rust or corrosion.

Best Practices for Instrument Sterilization

Implementing an effective instrument sterilization solution requires adherence to best practices. Here are essential strategies:

1. Maintain Cleanliness

Before sterilization, instruments should be thoroughly cleaned to remove all organic material. This step is critical, as soil can shield microorganisms from the sterilizing agents.

2. Proper Packaging

Instruments must be packaged correctly to ensure that they remain sterile after the sterilization process. Use breathable wraps or pouches designed for sterilization methods.

3. Validate Sterilization Processes

Regularly validate and monitor the sterilization process using biological indicators and chemical indicators to ensure that the methods used are effective.

The Role of Technology in Instrument Sterilization

Advancements in technology have significantly enhanced instrument sterilization processes. Automated systems and advanced monitoring devices help ensure that protocols are followed meticulously and that instruments are adequately sterilized.

1. Automated Sterilizers

Modern automated sterilizers come equipped with sophisticated features that allow for precise control over sterilization parameters, reducing the risk of human error.

2. Monitoring Systems

Utilizing real-time monitoring systems allows healthcare facilities to track sterilization cycles and ensure compliance with safety standards.

Challenges in Instrument Sterilization

Despite the best efforts, some challenges persist in achieving effective instrument sterilization. These include:

1. Material Compatibility

Not all instruments can withstand all sterilization methods. It is necessary to choose the right method based on the materials used in the instruments.

2. Complex Instrumentation

Instruments with complex designs may have areas that are difficult to clean and sterilize, necessitating specialized approaches to ensure proper sterilization.

Conclusion: Prioritizing Patient Safety with Instrument Sterilization Solutions

In conclusion, the significance of effective instrument sterilization solutions in healthcare cannot be overstated. By implementing the appropriate sterilization measures, adhering to best practices, and leveraging advanced technologies, healthcare facilities can significantly enhance patient safety and compliance. As a key player in the health and medical sector, Medalkan is committed to providing high-quality medical supplies and resources to support these critical processes, ensuring that healthcare providers are well-equipped to deliver safe and effective care.

Investing in effective sterilization solutions is not just a regulatory requirement; it is a vital component of responsible patient care. Let us work together to make healthcare environments safe and sterile.

Further Resources

For more information on instrument sterilization best practices and products, consider visiting the following resources:

- CDC Guidelines on Sterilization

- WHO Sterilization Guidelines

- Medalkan Instrument Sterilization Solutions